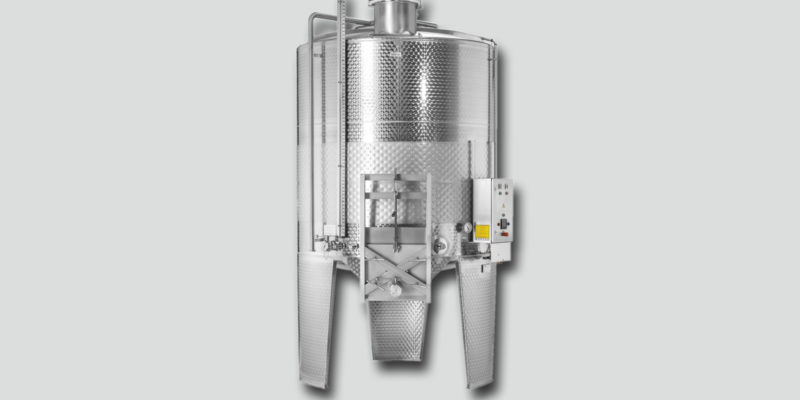

The mounting of the pneumatic cylinder on the tank top requires more space. In low-ceilinged cellar rooms this can sometimes pose a problem and often there is no possibility to use such tank systems.

Our innovative ‘internal plunger’ solves this problem once and for all. The well-tried immersion system via pneumatics is an integral part of the tank’s interior, thus allowing to reduce the tank’s height considerably. At a comparable total height of the tank systems the reduction of height allows 50% more capacity.

Due to the new level adjustment of the immersion wings the minimum filling amount can be reduced up to 40% of mash tank’s nominal volume. This way even smaller amounts can be processed.

STANDARD EQUIPMENT FOR RED WINE MASH INTERNAL PLUNGER FD-IT

(in case of divergent electronic specifications, the controller needs to be adjusted accordingly.)

TANK TOP

- Up to tank-Ø 2,000 mm made of AISI 316 stainless steel, surface IIId (2R)

- From tank-Ø of 2,000 mm upwards made of AISI 316 stainless steel, surface IIId (2R) / IIIc (2B)

- Ladder safety bow, lifting lugs

TANK SHELL

- Made of AISI 304 stainless steel, surface IIId (2R), marbled outside

TANK BOTTOM

- Up to tank-Ø of 2,000 mm made of AISI 304 stainless steel, surface IIId (2R)

- From tank-Ø of 2,200 mm upwards made of AISI 304 stainless steel, surface IIId (2R) / IIIc (2B)

- Free-standing on welded-on box-shaped legs

FILLER NECK

- Filler neck NW 400, located in tank top with an upright forward position (tank top with bead extrusion for complete ventilation)

- Flap lid with vent neck NW50 Rd 78 x 1/6″

TEMPERATURE MEASUREMENT

- Weld-on thread NW 10 DIN 11851

- Threaded sleeve with locking screw and cap nut NW 10 DIN 11851

- Bi-metal dial thermometer Ø 100 mm, measuring range -20 °C to +60 °C

SAMPLING

- Weld-on thread NW 20 DIN 11851

- Sampling tap with cap nut NW 20 DIN 11851